The Diode Laser Cutter And Engraver: A Comprehensive Guide

Welcome to this in-depth exploration of the . This innovative tool has revolutionized the way we approach cutting, engraving, and marking materials with precision and efficiency. Whether you’re a hobbyist, DIY enthusiast, or a professional in industries like woodworking, metalworking, or electronics, this guide will provide you with all the information you need to understand and utilize this versatile device effectively.

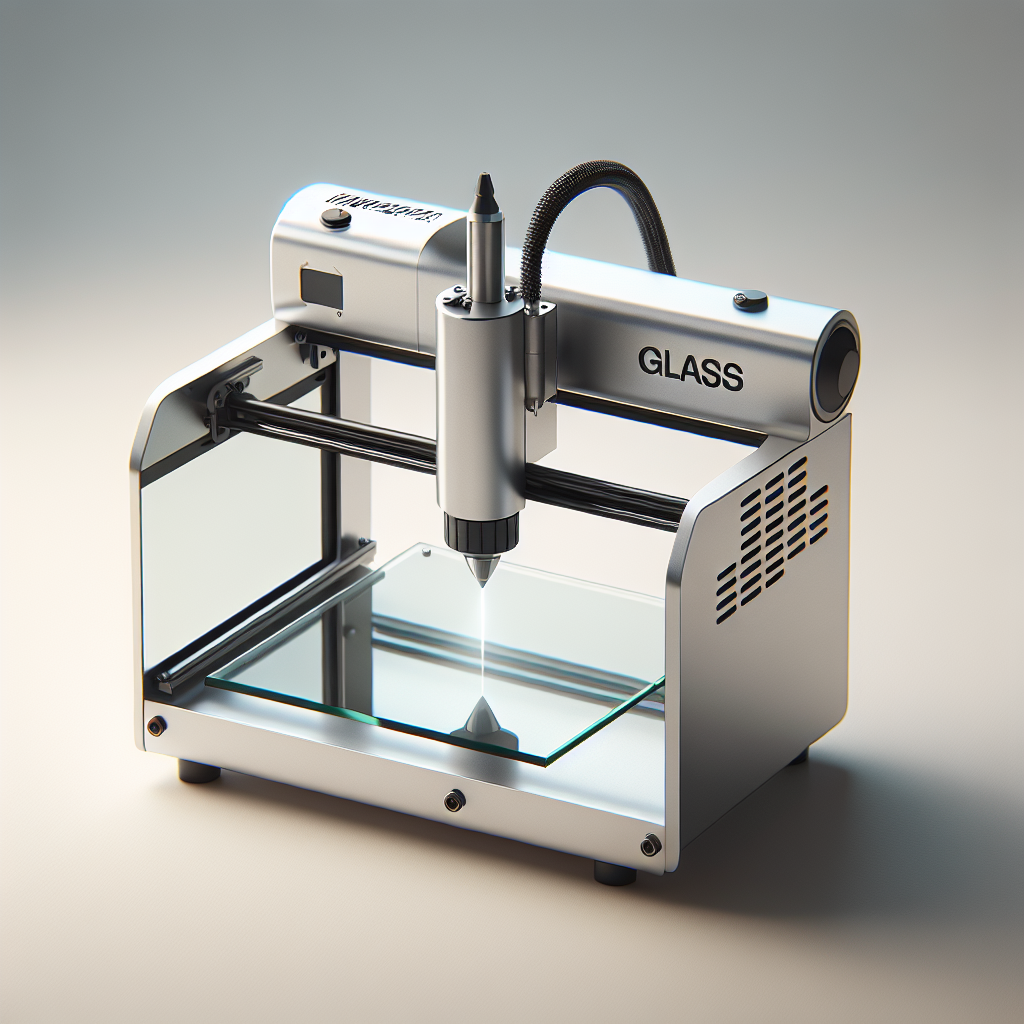

What Is A Diode Laser Cutter And Engraver?

A diode laser cutter and engraver is a compact, handheld device designed for cutting and engraving various materials with high precision. Unlike traditional tools that rely on mechanical blades or rotary bits, this device uses a focused beam of light to create intricate designs, patterns, and text on surfaces. The diode laser at the heart of this tool emits a concentrated beam of energy that vaporizes or melts the material being cut or engraved, leaving behind clean, precise results.

This technology is particularly useful for working with materials like plastic, wood, leather, acrylic, and even some types of metal. The handheld design makes it easy to maneuver, while its portability allows you to work on projects anywhere, anytime. Whether you’re creating custom jewelry, decorative items, or industrial components, this tool offers unparalleled flexibility and precision.

But how does it work? Let’s dive into the science behind this incredible device.

How Does A Diode Laser Cutter And Engraver Work?

The operation of a diode laser cutter and engraver is based on the principles of laser ablation. When the laser beam comes into contact with the material, it rapidly heats and removes tiny particles from the surface. This process creates the desired cuts or engravings without causing damage to the surrounding area. The wavelength and intensity of the laser can be adjusted to suit different materials and project requirements.

The device typically consists of a laser diode, a focusing lens, and a control system that allows you to adjust settings like power output, speed, and focus distance. Some models also come with software that enables you to import designs from your computer and transfer them directly onto the material. This makes it possible to create complex patterns and text with ease.

One of the key advantages of this technology is its ability to work on a wide range of materials. For example, plastic can be cut or engraved quickly and cleanly, while wood offers a natural finish that enhances the beauty of engravings. The versatility of the diode laser cutter and engraver makes it an indispensable tool for both small-scale projects and large-scale production.

Features And Benefits Of A Diode Laser Cutter And Engraver

Now that we’ve covered the basics of how this device works, let’s explore its features and benefits in more detail. Whether you’re a hobbyist looking for a fun new tool or a professional seeking to enhance your workflow, this section will highlight why a diode laser cutter and engraver is an excellent investment.

- Precision And Accuracy: The focused laser beam ensures that cuts and engravings are incredibly precise, even on delicate materials. This makes it ideal for creating intricate designs or detailed text.

- Versatility: As mentioned earlier, this tool can work with a wide range of materials, making it suitable for a variety of projects. Whether you’re working with plastic, wood, leather, or metal, the diode laser cutter and engraver delivers outstanding results.

- Portability: The compact, handheld design allows you to take this tool anywhere, enabling you to work on projects in the comfort of your home or on location.

- User-Friendly: Most models come with intuitive controls and software that makes it easy to create and transfer designs. Even if you’re new to laser cutting and engraving, you’ll be up and running in no time.

- Cost-Effective: Compared to traditional tools or outsourcing projects, investing in a diode laser cutter and engraver can save you money in the long run, especially for small-scale production or custom work.

If you’re still undecided, let’s look at some of the most common uses for this tool to give you a better idea of its potential.

Common Applications Of A Diode Laser Cutter And Engraver

The applications of a diode laser cutter and engraver are as diverse as the materials it can work with. Here are some of the most popular uses:

- Custom Jewelry: Create unique, custom-designed jewelry pieces by engraving or cutting intricate patterns into metals like stainless steel, titanium, or gold.

- Furniture And Decor: Add personalized touches to furniture, picture frames, or decorative items by engraving names, dates, or artistic designs.

- Signage And Marking: Use the tool to create professional-looking signs, labels, or logos on materials like acrylic, wood, or metal.

- Crafts And Hobbies: Hobbyists can use this device to create custom models, scale replicas, or decorative items with precision and ease.

- Electronics And Prototyping: For professionals in the electronics industry, this tool is perfect for cutting or marking circuit boards, components, or housing units.

With such a wide range of applications, it’s no wonder that the diode laser cutter and engraver has become a favorite among hobbyists and professionals alike. But before you dive into your next project, there are some important considerations to keep in mind.

Key Considerations For Using A Diode Laser Cutter And Engraver

While this tool is incredibly versatile and user-friendly, it’s essential to approach its use with caution. Here are some key considerations to ensure safe and effective operation:

- Safety First: Always wear appropriate safety gear when using a diode laser cutter and engraver, including goggles or glasses with UV protection. Never look directly into the laser beam, as it can cause serious eye damage.

- Material Compatibility: While this tool works with many materials, not all are suitable for laser cutting or engraving. Be sure to test the material on a small section before starting your project to ensure compatibility and avoid unexpected results.

- Focus And Alignment: Proper alignment of the laser beam is critical for achieving precise cuts and engravings. Regularly check and adjust the focus distance to maintain optimal performance.

- Maintenance: Like any tool, regular maintenance is essential to ensure long-term reliability. Clean the lens and housing regularly to prevent dust or debris from affecting performance. Always store the device in a dry, secure location when not in use.

By keeping these tips in mind, you’ll be able to maximize the potential of your diode laser cutter and engraver while minimizing risks and downtime.

Frequently Asked Questions About Diode Laser Cutter And Engraver

Now that we’ve covered the basics, let’s address some common questions that newcomers might have:

- Can I use this tool on metal? Yes, but it depends on the type of metal. Stainless steel and titanium are commonly used with diode lasers, while harder metals may require more advanced systems.

- Is it suitable for beginners? Absolutely! Most models come with user-friendly interfaces and software that make it easy to learn and use, even if you’re new to laser cutting and engraving.

- How powerful is a diode laser cutter and engraver? Power levels vary by model, but most are suitable for small-scale projects or hobby use. For larger industrial applications, higher-powered systems may be required.

- Can I cut through thick materials? While some models can handle thicker materials, it’s generally better suited for thinner sheets or smaller components. Always consult the specifications before purchasing to ensure it meets your needs.

If you have more specific questions, don’t hesitate to reach out to manufacturers or online communities for advice and support.

Conclusion

A diode laser cutter and engraver is a powerful tool that offers endless possibilities for creativity and productivity. Whether you’re a hobbyist looking to add a personal touch to your projects or a professional in need of a reliable, cost-effective solution, this tool has something to offer everyone.

With its versatility, portability, and user-friendly design, it’s no wonder that the diode laser cutter and engraver continues to grow in popularity. So why wait? Take the plunge and see what this amazing tool can do for you!

The Diode Laser Cutter and Engraver: A Comprehensive Guide

In the realm of precision craftsmanship and creative expression, few tools offer the versatility and power of a diode laser cutter and engraver. This guide delves into its functionalities, applications, and essential considerations to help you harness its potential effectively.

**What is a Diode Laser Cutter and Engraver?**

A diode laser cutter and engraver uses focused light energy to cut or etch materials, offering precision for intricate designs and patterns. Its portability and user-friendly design make it accessible for both hobbyists and professionals.

**Key Features**

- Precision: Ideal for detailed work.

- Versatility: Works with various materials like plastic, wood, leather, and metals (e.g., stainless steel, titanium).

- Portability: Compact and handheld for on-the-go use.

- Ease of Use: Intuitive controls and software-friendly.

**Applications**

- Custom Jewelry: Engrave or cut intricate designs into metals.

- Furniture & Decor: Personalize items with names, dates, or artistic touches.

- Signage & Marking: Create professional signs or logos on acrylic, wood, or metal.

- Crafts & Hobbies: Ideal for models, replicas, and decorative items.

- Electronics & Prototyping: Cut or mark circuit boards and components.

**Important Considerations**

- Safety: Wear protective eyewear; avoid direct laser exposure.

- Material Compatibility: Test materials before full use.

- Focus & Alignment: Regularly check for optimal performance.

- Maintenance: Clean the lens and store securely.

**FAQs**

- Can it cut metal? Yes, particularly stainless steel and titanium.

- Suitable for beginners? Absolutely; user-friendly interfaces ease learning.

- Power levels? Vary by model; most suit small-scale projects.

- Cutting thick materials? Better suited for thinner sheets.

**Conclusion**

The diode laser cutter and engraver is a must-have tool for those seeking precision and creativity. Its adaptability and user-friendly nature make it perfect for both personal and professional use, unlocking endless possibilities for your projects.

Embrace the potential of this versatile tool and elevate your craftsmanship today!